The optimal climate for the pig – what do you have to pay attention to?

The right climate in the pig stall has an effect on the welfare and health of the animals. Correctly designed ventilation therefore also has a positive effect on production results.

Contents

- Importance of ventilation systems

- Recommended reference values for climate parameters for pigsties

- Maximum contents for harmful gas concentration (according to TSchNutzt)

- Which ventilation system should be selected for the pig stall?

- Negative pressure ventilation in the pig stall

- What is to be considered?

- Ventilation in winter

- Ventilation in summer

- How does the high pressure cooling system work?

Importance of ventilation systems

The main task of ventilation is to replace used air, but also to help maintain the optimum temperature in the pig stall to reduce heat stress.

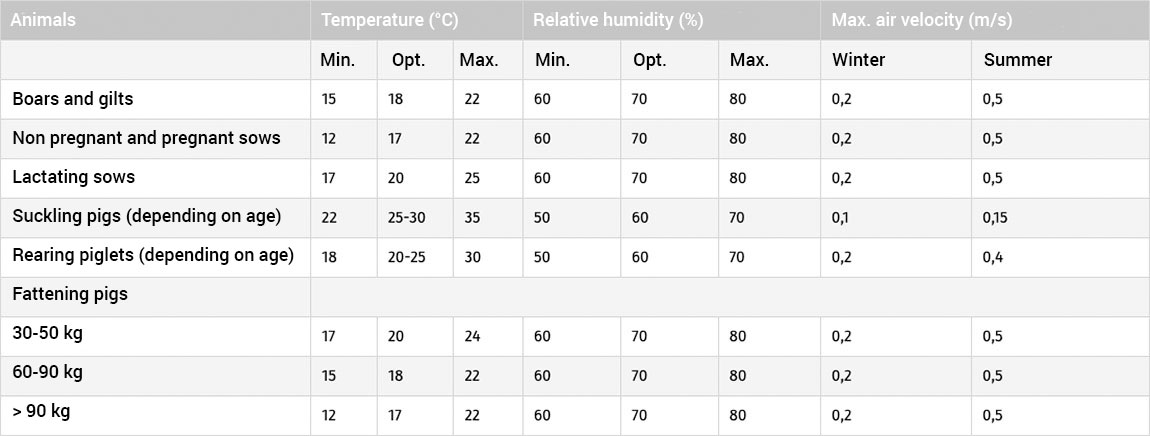

Recommended reference values for climate parameters for pigsties

Maximum contents for harmful gas concentration (according to TSchNutzt)

| Harmful gas | Reference values for max. concentrations in the animal area (ppm/m3 air) |

|---|---|

| Ammonia (NH3) | 20 |

| Carbon dioxide (CO2) | 3000 |

| Hydrogen sulfide (H2S) | 5 |

Which ventilation system should be selected for the pig stall?

The choice of ventilation method must always be based on the effectiveness of the mechanism – ensuring the right microclimate for the animals. The air exchange must be regulated depending on the temperature and humidity inside the building and the conditions prevailing outside the building.

The external conditions and the activity of the pigs affect the change in climatic conditions during the day. A manual control is therefore not feasible. A practical solution is the use of automatic systems with climate computers that record all relevant climate parameters and control them independently.

Negative pressure ventilation in the pig stall

The most widespread and effective mechanical ventilation system is vacuum ventilation, as it offers the greatest possibilities for regulating the air flow and allows an even distribution of air in the building without creating draughts in the areas where the pigs are lying down.

In this system the used air is actively transported out of the pig stall by fans. Extraction takes place either above or below the animal area and is normally discharged via chimneys embedded in the roof of the building. The active air discharge creates suction at the other end, drawing fresh air into the building from outside. The supply air can enter the pig stall and the animal area via several routes. Very often, the side walls have large openings for a central supply air duct, from which the fresh air is distributed in the pig stall.

What must be observed in terms of ventilation systems?

In order to achieve the correct air movement and thus efficient ventilation, supply and exhaust air technology must be correctly positioned and dimensioned.

The correct functioning of the ventilation system must be checked daily and a more extensive climate check should be carried out at regular intervals. A wide range of faults such as malfunctions in the air circulation (e.g. dirty and thus clogged supply air, false air due to leaking doors or manure slides), defects or malfunctions (e.g. incorrect measured values, fans running the wrong way round) can be detected and eliminated.

Ventilation in winter

Low outside temperatures in winter and the associated cooler supply air in winter mean that the air rates in the pig stall are reduced in order to keep the temperatures in the pig stall within the comfort range of the pigs. The accumulation of harmful gases in the animal area and excessive humidity can be problematic. Especially for younger pigs, it is recommended to have additional heating in the compartment or to heat the supply air before it is introduced into the compartment in order to keep the temperature and air rate at an optimum level for the animals.

Ventilation in summer

Unlike ventilation in winter, the main task of ventilation in summer is to transport heat out of the animal area. However, even ventilation running at full load is often no longer sufficient, especially when outside temperatures in midsummer are very high. Additional measures must then be taken to maintain the animals’ performance and prevent losses. There are also a wide range of technical possibilities for this – but high-pressure cooling is particularly noteworthy.

How does the high pressure cooling system work?

Water is passed through fine nozzles at high pressure, causing the water to break down into a very fine mist that immediately evaporates in the hot air. This ensures effective cooling with a temperature reduction of 5 to 8 degrees Celsius.

The system can be placed in the central supply air shaft, but works just as well directly in the compartment. When placed in the compartment, some systems can also be used to soak and disinfect the pig stall equipment.

A coupling of the cooling system with the climate control system is recommended so that the air humidity does not become too high.